About Outside.Center

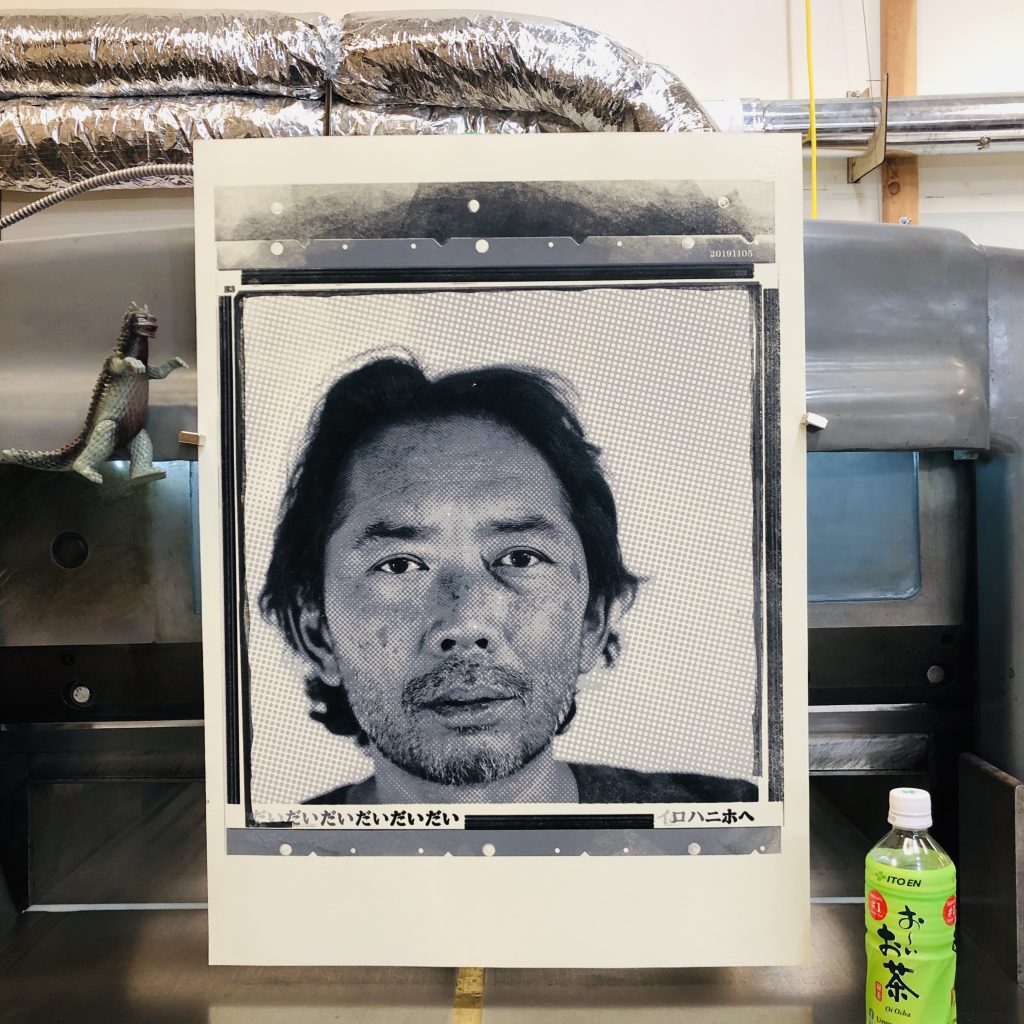

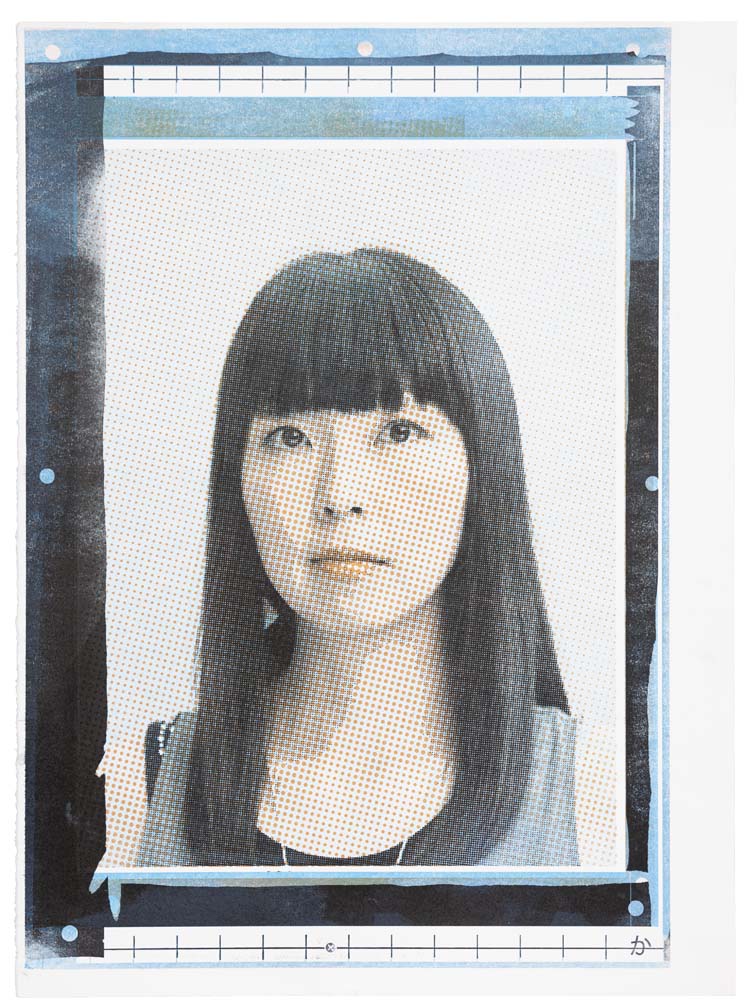

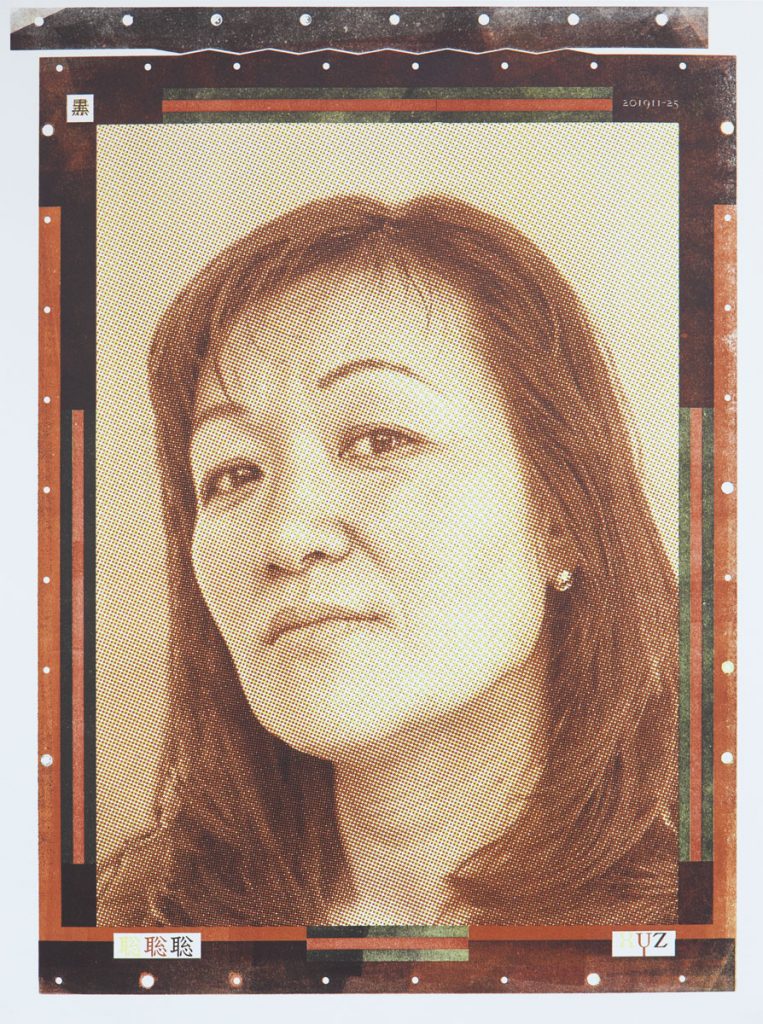

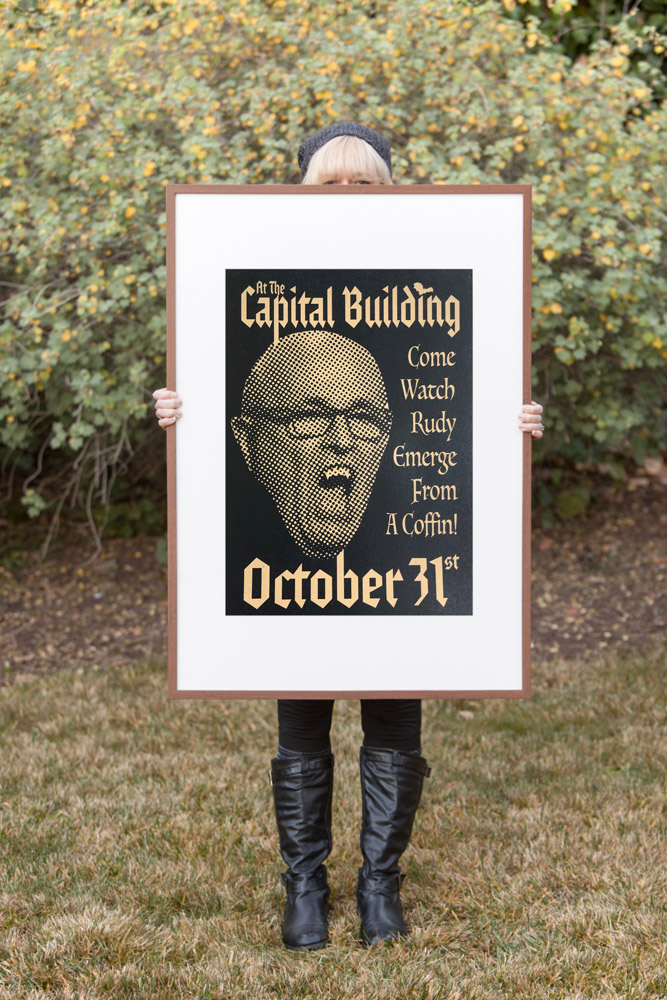

I produce large format letterpress prints using a newly modernized ginormous 5,000 lbs Vandercook Proving Machine 232P (a.k.a. Hilda) from the late 1930s. The prints are hardly perfect yet really fun to look at; Large, rough yet ultra fine (!!)…

Gozilla for scale.

The papers are cut using an even more massive 6,300 lbs paper cutter (a.k.a. Matilde) from the 50s. Cutting parent-sheets, it’s awesome and scary at the same time. The giant plates are engraved using a laser engraver from this century. He has yet to be named. I’m taking suggestions.

Please visit my YouTube channel if you are curious how these are created.

The ADD part of me would like to inform you that the combined scrap value of the cast iron in the machineries above is approximately US$250 in good days but it’s safe to say that unimaginable amount were spent in caring and having them moved, from there to here to here to there, over the past years.

I dabble in medicine(?), politics and DIYs. I have neither medical degrees nor claim to have any grifting abilities, so please be advised that you use a common sense before attempting to repeat anything I do.

I dabble in electronics and other DIY attempts (just enough to be dangerous, as some would say) to make things better:

RIP Dahlia

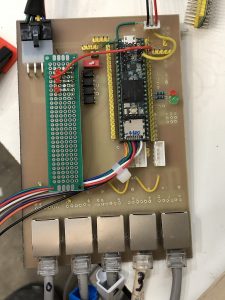

Press Servo Controller

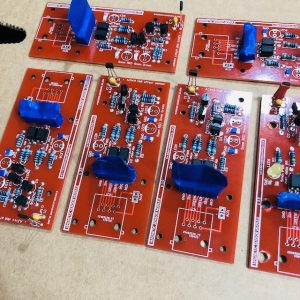

Press Servo Controller PCB

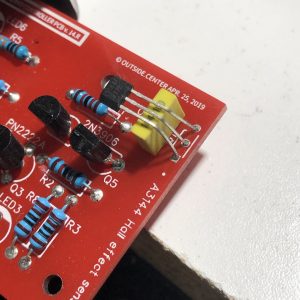

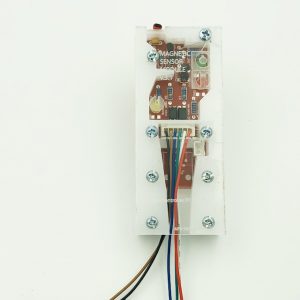

Press Magnetic Sensor PCB

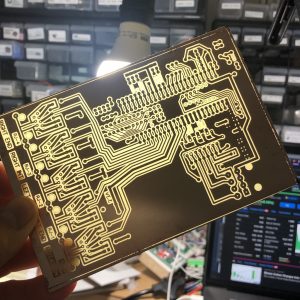

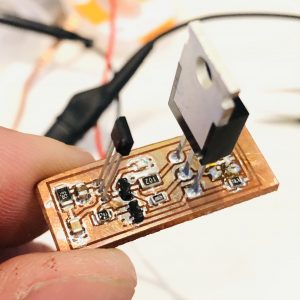

Etching PCBs

Etching PCBs

Magnetic Foot Pedal for Vandercook Letterpress

Welding a drivetrain frame for the Vandercook

New Servo and Original Worm Gear Box on the New Frame

Finished Servo Drivetrain Frame

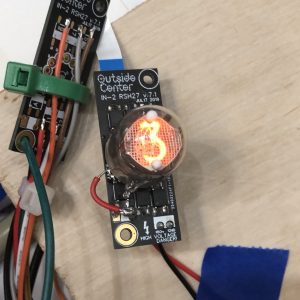

Finished Press Magnetic Sensor

Magnetic Sensor PCBs with Parts Soldered on

Top Secret Nixie Tube Thing…

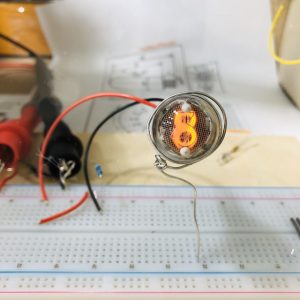

Testing Nixie Tubes

Low Impedance Switch for RileyLink

Waterproof Case for RileyLink

Press Paper Guide

Press Table